Innovation is the cornerstone of progress in the realm of manufacturing. From the invention of the assembly line to the digital revolution, each era brings forth transformative technologies that redefine how we create, produce and consume goods.

Among these innovations stands additive manufacturing, more commonly known as 3D printing. With its ability to turn digital designs into physical objects layer by layer, additive manufacturing has emerged as a game-changer across industries, promising unlimited possibilities and unprecedented efficiencies. Notably, the global 3D printing market is projected to hit over $63 billion by 2025.

Let’s find out more about additive manufacturing.

Read: AI for Your Industry: The Manufacturing Sector

What Is Additive Manufacturing?

At its core, additive manufacturing is a process of building three-dimensional objects and prototypes by adding successive layers of material. This is in contrast to traditional subtractive methods that involve cutting away material from a solid block or formative methods that create objects by molding materials into shape with heat or pressure. Additive manufacturing enables intricate geometries and customized designs that were previously unattainable, revolutionizing how we conceptualize and produce objects.

As additive manufacturing continues to evolve, its impact will only grow stronger. From revolutionizing supply chains to empowering individuals, it promises a more sustainable, efficient and inclusive future.

How Additive Manufacturing Works and the Seven Types

The first part of additive manufacturing is creating a digital design, often with computer-aided design (CAD) software or a 3D scanner. The design is then “sliced” into hundreds or even thousands of thin layers before being uploaded to the 3D printer, acting as a blueprint for the object. From there, additive technology can use one of these seven technologies.

- The most commonly used technology is material extrusion, which is also called fused deposition modeling (FDM) or fused filament fabrication (FFF). This is when a spool of thermoplastic filament like acrylonitrile butadiene styrene (ABS) is melted and then deposited through a heated extrusion nozzle in horizontal and vertical layers until the object is complete.

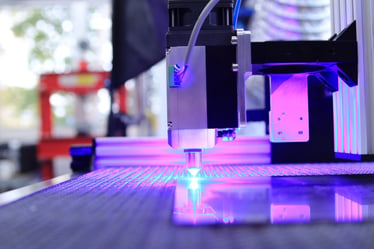

- Another technology is vat photopolymerization, which is when a light source, usually a laser or projector, solidifies a liquid photopolymer layer by layer until the object is complete. Stereolithography (SLA) is an example of this, and it is when an ultraviolet laser is shined into a vat of photopolymer and traces that object on its surface. Another variation is digital light projector (DLP), which exposes the polymer to light from a digital light processing projector.

- Powder bed fusion uses a heat source on powdered polymers or metals to melt them so they can connect to another particle, eventually forming an object. This includes selective laser sintering (SLS), which uses a high-powered laser to melt the powder and fuse particles together.

- Material jetting works similarly to an inkjet printer, except instead of ink, a nozzle deposits droplets of liquid photosensitive material one at a time on a platform before being hardened by UV light or heat.

- Binder jetting is similar to material jetting, but it uses two materials: a powder base material and a liquid binder. The printer lays a layer of the powder onto a platform and then adds the binder to connect the particles, creating a solid object; this technology does not require heat.

- Sheet lamination, including laminated object manufacturing and ultrasonic additive manufacturing, is when individual sheets of material are cut to shape and then laminated together with welding, heat, pressure or adhesive.

- Direct energy deposition (DED) uses a multi-axis nozzle to deposit material, usually metal, onto a platform while a laser or electronic beam melts it, forming a solid object.

After the object is printed, it often requires post-processing: sanding, smoothing, heat treatment or more. Post-processing can differ depending on the material and the 3D printer.

What Materials Does Additive Manufacturing Use?

Additive manufacturing uses a variety of materials:

- Metals (stainless steel, solder, aluminum, titanium, nickel, chromium, copper)

- Plastics and polymer composites

- Edibles (chocolate, cheese)

- Ceramics

- Plastics

- Resins

- Glass

- Foams

- Gels

- Concrete

Applications Across Industries

Although the concept of 3D printing dates back to the 1980s, it’s only in recent years that the technology has gained widespread attention and adoption. Initially used for rapid prototyping in industries like aerospace and automotive, 3D printing has expanded its reach to encompass diverse fields, including healthcare, architecture, fashion and more. This versatility is a key factor in its appeal, as it helps simplify processes, cut costs and enhance efficiency across a wide range of applications.

- Aerospace and automotive: The aerospace and automotive industries have embraced 3D printing for its ability to produce lightweight yet robust components, leading to fuel-efficient aircraft and vehicles. Companies are leveraging additive manufacturing to fabricate complex engine parts and tools, lightweight structures and customized interiors, pushing the boundaries of performance, production and design. Weight is a crucial aspect, as it can affect the functionality, so lowering weight can be significant.

- Architecture and construction: In architecture and construction, 3D printing is revolutionizing how buildings are designed and made. From rapid prototyping of scale models to on-site fabrication of structural components, the technology offers new tools for innovation and sustainability. With advancements in materials and construction techniques, 3D-printed buildings are poised to reshape urban landscapes and address housing challenges worldwide.

- Consumer goods: From jewelry to toys and footwear to eyewear, 3D printing is democratizing design and manufacturing, allowing customers to participate in the creation process. Artists and designs are leveraging this technology to unleash their creativity, producing customizable and personalized products catering to individual tastes and preferences.

- Education: 3D printing has become a powerful tool in education, especially in Science, Technology, Engineering and Math (STEM) subjects. This technology enables students and teachers to bring their ideas to life. It can help develop immersive learning models and advance research while also offering students first-hand experience at using additive manufacturing, helping them understand complex problems and encouraging creative problem-solving.

- Healthcare: In healthcare, 3D printing has sparked a medical revolution, enabling the creation of patient-specific implants, prosthetics and anatomical models for surgical planning. From personalized hearing aids to intricately detailed organ replicas, the technology has empowered clinicians to deliver more precise and effective treatments while reducing costs and production times. Additive manufacturing also extends into the dental industry with molds for clear aligners, bridges, crowns and dentures, as well as audiology for hearing aids, hearing protection and earbuds.

Benefits of Additive Manufacturing

Many benefits come with additive manufacturing:

- Production speed: Traditional manufacturing processes can take weeks or even months to produce a prototype. 3D printing is ideal for rapid prototyping, allowing them to be designed, developed, tested and refined in a few days. This saves time and money before the prototype goes to market and often bypasses supply-chain issues.

- Design freedom: Additive manufacturing allows users to create complex, innovative geometries that would normally be difficult, costly or impossible to achieve with traditional processes. 3D printing can turn multiple pieces into one part, which can help reduce weight, alleviate weakness and cut down on assembly time.

- Less waste: With additive manufacturing, there is less material waste than traditional methods; since layers are put on top of each other instead of the object being cut away from material, leftover material is left. Additive manufacturing can reduce energy use by 25% and waste and materials costs by up to 90%.

- Higher customization: 3D printing can easily create custom designs with various materials, whereas custom designs using traditional production methods mean new tooling configurations or molds for each material used, which can cost time and money.

- Less storage space: Being able to print parts when needed removes the need for storage warehouses, which typically hold hundreds, if not thousands, of replacement parts. It would also eliminate the time spent waiting for the replacement part to ship and arrive at the needed location.

Additive Manufacturing Challenges

Although the potential of additive manufacturing is vast, it’s not without its challenges and issues, posing hurdles to widespread adoption.

3D printing machines and software programs can be expensive, and the limited materials used can be difficult to source. Some of these materials are also more brittle than others, causing them to have lower strength.

Although 3D printing is faster and more cost-effective for prototypes and small batches of items, it can’t compete against the speed of mass projection methods. 3D printers are also limited in the size of objects they can make.

Another challenge with additive manufacturing is that the printers have limited accuracy and tolerance, meaning the final product might differ from the original design. Although this can be fixed with post-processing, it should be assumed from the beginning that 3D-printed objects might not always be exact.

Additive Manufacturing for Minnesota and Florida Manufacturers

As mentioned above, additive manufacturing is a technology transforming various sectors. One of them is manufacturing, an industry that Thriveon can help revolutionize with IT strategies.

Our proactive managed IT services bring the latest in industry standards and productivity, as well as make manufacturers more efficient. We help our Minnesota and Florida manufacturers prevent costly downtime, improve internal communication and align their IT strategy with their overall business goals.

Schedule a meeting with us now for more information and to see how additive manufacturing can improve your business.